| Availability: | |

|---|---|

| Quantity: | |

The Air Compressor Online Soft Starter from YINAN ELECTRIC is an advanced, efficient solution designed for air compressor systems. This soft starter reduces inrush currents, ensuring a smooth start-up for compressors and extending the lifespan of motors and other components. With easy integration, the Air Compressor Online Soft Starter provides reliable, cost-effective performance for industrial and commercial applications.

The Compact Online Soft Starter for Air Compressor represents a breakthrough in motor control technology, specifically engineered to optimize the performance of air compressor systems across industrial, commercial, and institutional applications. This advanced device provides smooth, gradual acceleration of compressor motors, eliminating the harmful effects of sudden voltage surges associated with direct-on-line starting. By reducing inrush current during startup, the soft starter minimizes mechanical stress on compressor components, significantly extending equipment lifespan while reducing energy consumption. Compliant with IEC 60947-4-2 standards, this compact solution integrates seamlessly with both new installations and retrofit projects, supporting a wide range of air compressor types including rotary screw, reciprocating, and centrifugal models. Its space-saving design and intelligent control capabilities make it an essential component for efficient compressed air systems.

Utilizing advanced semiconductor technology, the soft starter reduces inrush current by 50-70% compared to direct starting methods, preventing voltage dips in electrical systems and reducing mechanical wear on compressor belts, bearings, and gears. The adjustable ramp time (0.5 to 60 seconds) allows precise matching to specific compressor requirements.

Equipped with multi-layer protection mechanisms, the device safeguards compressors against overload, phase imbalance, undervoltage, overvoltage, and overheating conditions. The built-in thermal protection system with Class 10 overload rating ensures reliable operation even in demanding environments.

Integrated sensors continuously monitor key operating parameters including current, voltage, power factor, and motor temperature. Real-time data is displayed on the intuitive LCD interface, with configurable alarms for abnormal conditions ensuring prompt maintenance response.

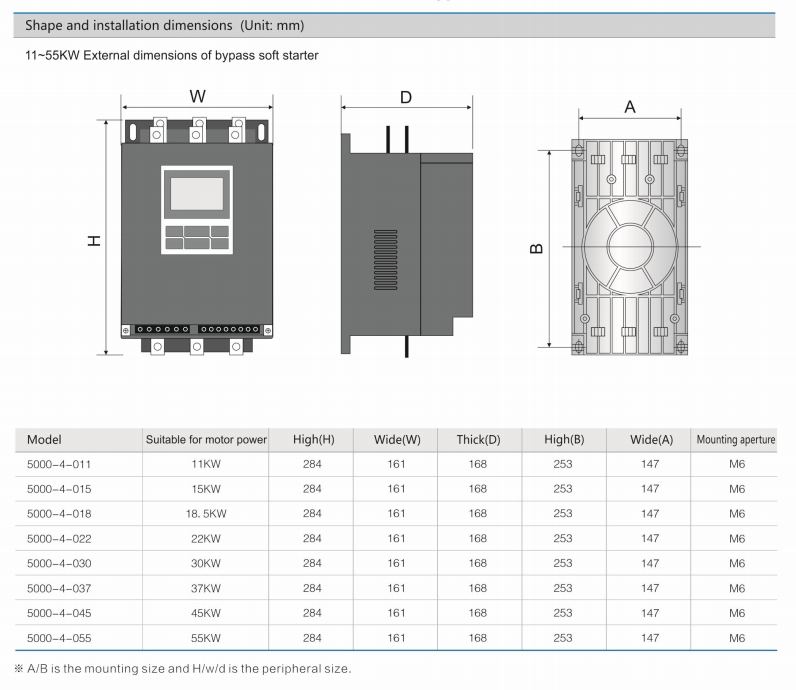

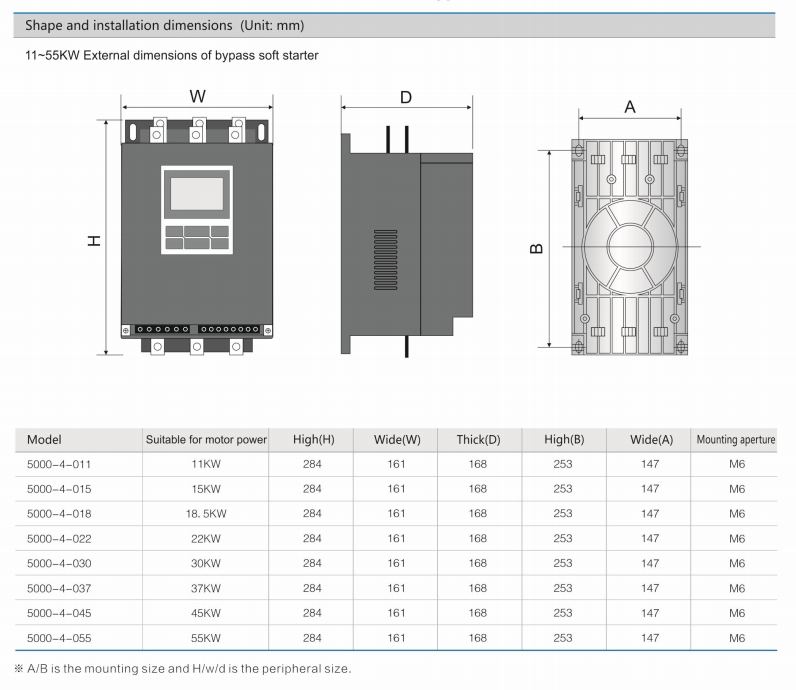

With a footprint 30% smaller than traditional soft starters, the unit fits easily into existing electrical cabinets. It supports standard communication protocols including Modbus RTU, enabling seamless integration with building management systems and SCADA networks for centralized control.

In manufacturing facilities, the soft starter optimizes operation of large rotary screw compressors used for pneumatic tools, assembly line automation, and process control systems, reducing maintenance costs and improving system reliability.

Commercial buildings benefit from reduced startup stress on air conditioning and refrigeration compressors, extending equipment life while preventing voltage fluctuations that can affect sensitive electronic equipment.

The soft starter provides reliable control for compressors in food processing facilities, where consistent air pressure is critical for packaging machinery, pneumatic conveyors, and process automation systems.

Hospitals and medical centers utilize the soft starter to ensure stable operation of critical air compressor systems supporting life-saving equipment, laboratory instruments, and climate control systems.

The device supports single-phase and three-phase air compressor motors ranging from 0.75kW to 75kW (1HP to 100HP), making it suitable for most commercial and light industrial applications.

By eliminating startup inrush current and optimizing motor performance, typical energy savings range from 10-15% in continuous operation, with additional savings from reduced maintenance and downtime.

Yes, the unit features a user-friendly interface with guided setup procedures. While basic electrical knowledge is required, no specialized training is necessary, and the installation typically takes less than 2 hours.

Housed in an IP20-rated enclosure for indoor use, the soft starter operates reliably in temperatures ranging from -10°C to 50°C (14°F to 122°F) with relative humidity up to 95% (non-condensing).

The device is designed for maintenance-free operation with no moving parts. Annual inspection of electrical connections and cleaning of cooling vents is recommended to ensure optimal performance.

The Air Compressor Online Soft Starter from YINAN ELECTRIC is an advanced, efficient solution designed for air compressor systems. This soft starter reduces inrush currents, ensuring a smooth start-up for compressors and extending the lifespan of motors and other components. With easy integration, the Air Compressor Online Soft Starter provides reliable, cost-effective performance for industrial and commercial applications.

The Compact Online Soft Starter for Air Compressor represents a breakthrough in motor control technology, specifically engineered to optimize the performance of air compressor systems across industrial, commercial, and institutional applications. This advanced device provides smooth, gradual acceleration of compressor motors, eliminating the harmful effects of sudden voltage surges associated with direct-on-line starting. By reducing inrush current during startup, the soft starter minimizes mechanical stress on compressor components, significantly extending equipment lifespan while reducing energy consumption. Compliant with IEC 60947-4-2 standards, this compact solution integrates seamlessly with both new installations and retrofit projects, supporting a wide range of air compressor types including rotary screw, reciprocating, and centrifugal models. Its space-saving design and intelligent control capabilities make it an essential component for efficient compressed air systems.

Utilizing advanced semiconductor technology, the soft starter reduces inrush current by 50-70% compared to direct starting methods, preventing voltage dips in electrical systems and reducing mechanical wear on compressor belts, bearings, and gears. The adjustable ramp time (0.5 to 60 seconds) allows precise matching to specific compressor requirements.

Equipped with multi-layer protection mechanisms, the device safeguards compressors against overload, phase imbalance, undervoltage, overvoltage, and overheating conditions. The built-in thermal protection system with Class 10 overload rating ensures reliable operation even in demanding environments.

Integrated sensors continuously monitor key operating parameters including current, voltage, power factor, and motor temperature. Real-time data is displayed on the intuitive LCD interface, with configurable alarms for abnormal conditions ensuring prompt maintenance response.

With a footprint 30% smaller than traditional soft starters, the unit fits easily into existing electrical cabinets. It supports standard communication protocols including Modbus RTU, enabling seamless integration with building management systems and SCADA networks for centralized control.

In manufacturing facilities, the soft starter optimizes operation of large rotary screw compressors used for pneumatic tools, assembly line automation, and process control systems, reducing maintenance costs and improving system reliability.

Commercial buildings benefit from reduced startup stress on air conditioning and refrigeration compressors, extending equipment life while preventing voltage fluctuations that can affect sensitive electronic equipment.

The soft starter provides reliable control for compressors in food processing facilities, where consistent air pressure is critical for packaging machinery, pneumatic conveyors, and process automation systems.

Hospitals and medical centers utilize the soft starter to ensure stable operation of critical air compressor systems supporting life-saving equipment, laboratory instruments, and climate control systems.

The device supports single-phase and three-phase air compressor motors ranging from 0.75kW to 75kW (1HP to 100HP), making it suitable for most commercial and light industrial applications.

By eliminating startup inrush current and optimizing motor performance, typical energy savings range from 10-15% in continuous operation, with additional savings from reduced maintenance and downtime.

Yes, the unit features a user-friendly interface with guided setup procedures. While basic electrical knowledge is required, no specialized training is necessary, and the installation typically takes less than 2 hours.

Housed in an IP20-rated enclosure for indoor use, the soft starter operates reliably in temperatures ranging from -10°C to 50°C (14°F to 122°F) with relative humidity up to 95% (non-condensing).

The device is designed for maintenance-free operation with no moving parts. Annual inspection of electrical connections and cleaning of cooling vents is recommended to ensure optimal performance.